Virtual Design and Construction (VDC) is being used more frequently as the construction industry changes quickly to effectively convert client building performance objectives into measurable project and production plans. Today Engisoft Engineering will help you to learn about workflow and virtual modeling through VDC, as well as how it can enhance the building experience.

What is VDC?

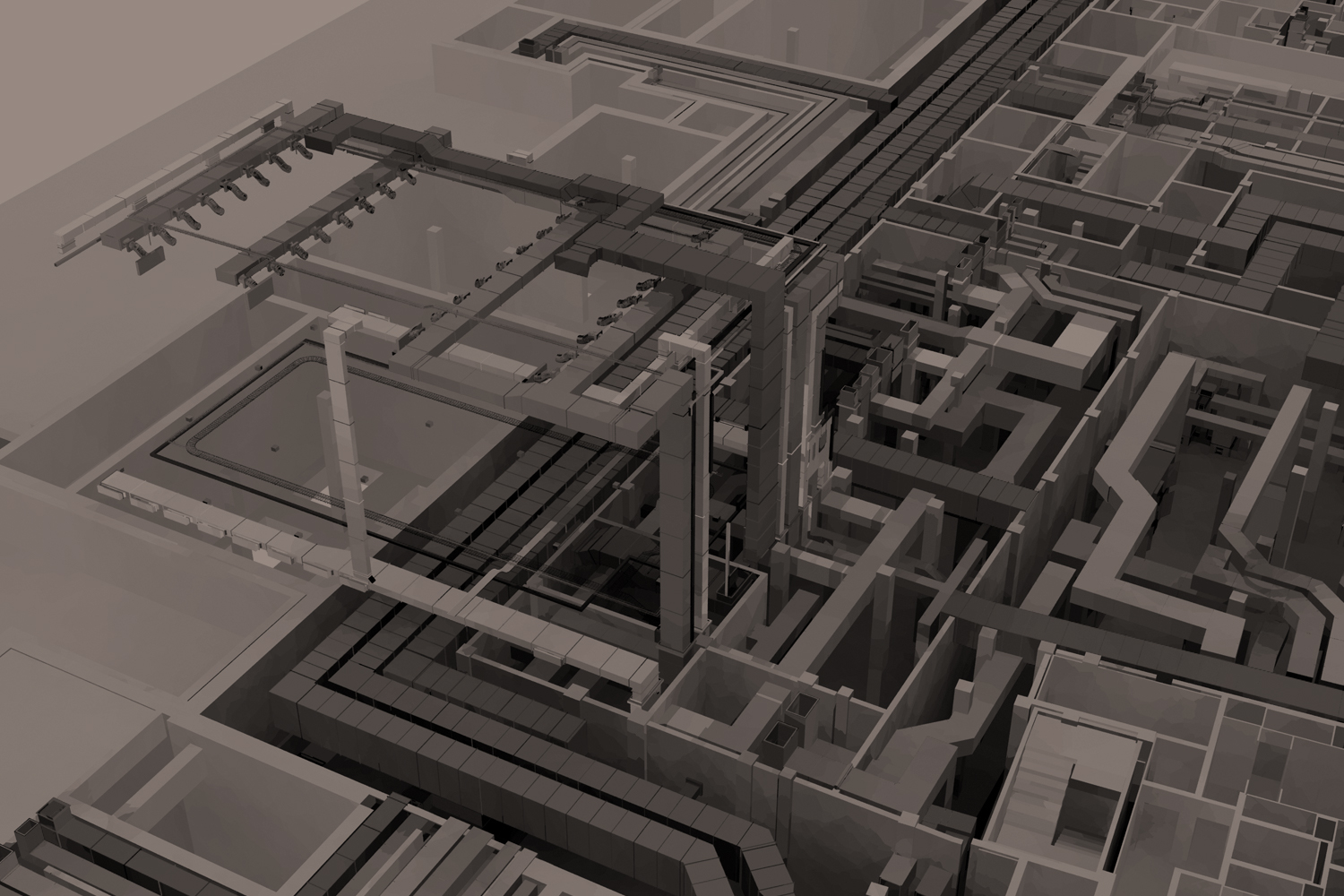

VDC is a kind of technology that creates digital models of buildings and project sites. VDC models are used by architects, engineers, and contractors to visualize and plan various aspects of building designs, procedures, schedules, and budgets. Building information modeling (BIM) is used in virtual design and construction (VDC) to manage performance models for design-construction projects. To achieve particular goals, it can be used to manage the product, work processes, and even the organization of the operation team.

We can virtually design a project, monitor progress, optimize workflows, reduce waste, and validate installations thanks to this technology. As a result, quality can be increased and risk can be reduced while the workflow is improved.

What Makes VDC Important?

Innovative business leaders are always looking for new ways to increase profitability, and for design and construction professionals, profitability is based on delivering results on time and within budget. The AEC sector is quickly moving in the direction of VDC. Experts can manage projects more holistically thanks to the digital environment, which also provides a solid foundation for significant performance improvements. Industry leaders have already shifted to a VDC strategy, laying the groundwork for a time when owners will only expect results from a virtual platform for collaboration.

The Structure of VDC

Before making a significant investment of time or money, VDC in building design aims to understand the complexity of a project and anticipate potential obstacles. The following tools are the way to achieve the implementation of VDC

Integrated Concurrent Engineering (ICE)

Through the use of the most advanced technologies, Integrated Concurrent Engineering (ICE), a social method developed from Extreme Collaboration and already employed by NASA, aims to facilitate decision-making and enhance communication. To create and evaluate multidisciplinary VDC models quickly and accurately, this methodology for the VDC aims to schedule meetings with the design team and allow stakeholders from various disciplines to participate at the same time. You can shorten the time spent making decisions, enhance output quality and achieve greater interdisciplinary integration.

Project Production Management (PPM)

The process part of VDC is known as PPM (Product Production Management). When applied to a project, product production management clearly defines the project’s goals, offers a comprehensive overview of the entire project, and highlights the tasks that require the most focus. It is a planning tool that enables the management of the project’s execution. It defines using systems and methodologies:

Project variability must be reduced through the use of workflow design resources.

The project delivery can be understood, controlled, and enhanced with PPM’s use in VDC design.

Building Information Modeling (BIM)

Virtuality, or the use of technology to enhance projects, is a feature of BIM. It is a method for getting a digital and visual representation of the project the team is working on along with details about each item in the structure. BIM is vital to ICE sessions for Presenting project challenges to the team and clients is made simple; data collection and 3D visualization aid in decision-making.

Metrics

The proper metrics must be monitored in order for each component to achieve the goals of the VDC process. These metrics are crucial for pinpointing adjustments that should be made for ongoing process improvement. Based on the determined objectives, Key Performance Indicators (KPIs) to be monitored for project success should be selected.

Benefits of VDC

The extreme optimization of the management phase is the biggest innovation brought by the use of VDC in construction design and planning. Here are some of the main benefits of using VDC:

- A significant improvement in team communication thanks to the use of the ICE system, which also optimizes communication between the various sectors and eliminates any process delays brought on by the incomplete integration of all the disciplines involved in a single project.

- The PPM methodology makes it possible to clearly define the process goals, final products, raw materials, information, and activities that require the most focus from the start. As a result, the project is better planned, there are fewer conflicts and unforeseen incidents on the construction site, and models and design solutions don’t need to be revised as often.

- By incorporating BIM into the VDC process, a realistic virtual model is created that allows all participants to quickly, easily, and clearly, visualize the project as a whole. This allows for simultaneous work and the blending of various solutions while avoiding expensive emergency solutions.

VDC vs. BIM

- Both are built on cooperation and informed communication, but VDC is a broader idea that involves BIM as a method of operation.

- In actuality, VDC refers to the method by which BIM is applied throughout a project’s lifecycle. BIM specifically creates a virtual building’s construction with related information. VDC plans the entire construction process using BIM models, including components like the budget, cost estimation, and planning (4D, 5D, etc.).

- Finally, while BIM organizes the models and project documents used in these processes, VDC organizes the processes themselves.

FAQ

What does VDC stand for BIM?

Virtual Design and Construction

Why do we need virtual designs?

Currently, a number of construction companies use virtual design and construction to produce eye-catching, comprehensive 3D models as well as early, precise cost estimates and scheduling data.

Who invented VDC?

CIFE – Center for Integrated Facility Engineering at Stanford University in California first developed and conceptualized the VDC (Virtual Design and Construction) method in 2001, during the early stages of BIM. Professor Martin Fischer, the director of CIFE, is credited as the methodology’s pioneer.

Is BIM part of VDC?

BIM is not always a part of VDC, and it can be used without being regarded as a component of VDC. BIM is more focused, but both develop working methods to successfully complete a business goal.

What does a VDC engineer do?

Engineers who specialize in virtual design and construction (VDC) oversee the planning, computer modeling, and visualization of construction projects. In order to develop a comprehensive construction plan, they collaborate closely with BIM modelers, architects, and clients.

Source:

- Architectural BIM Modeling Services.

- Structural BIM Modeling Services.

- MEP BIM Modeling Services.

- MEP Coordination Services.

- Infrastructure BIM Modeling Services