Digital twins are quickly becoming a vital tool in architecture and building. These days, many companies create digital twins of their facilities in order to better monitor and manage everything from assets to space. They might be unaware that there is already a digital twin. Because they depict the project on a dynamic plane, digital twins in construction are becoming more common during the development and construction phases of a building. It emphasizes the critical role that digital building information plays throughout a property’s life cycle, from the planning stages to the later stages of development as a workplace.

Today Engisoft Engineering has brought all the information about Digital Twins in one place for you.

What Is A digital twin?

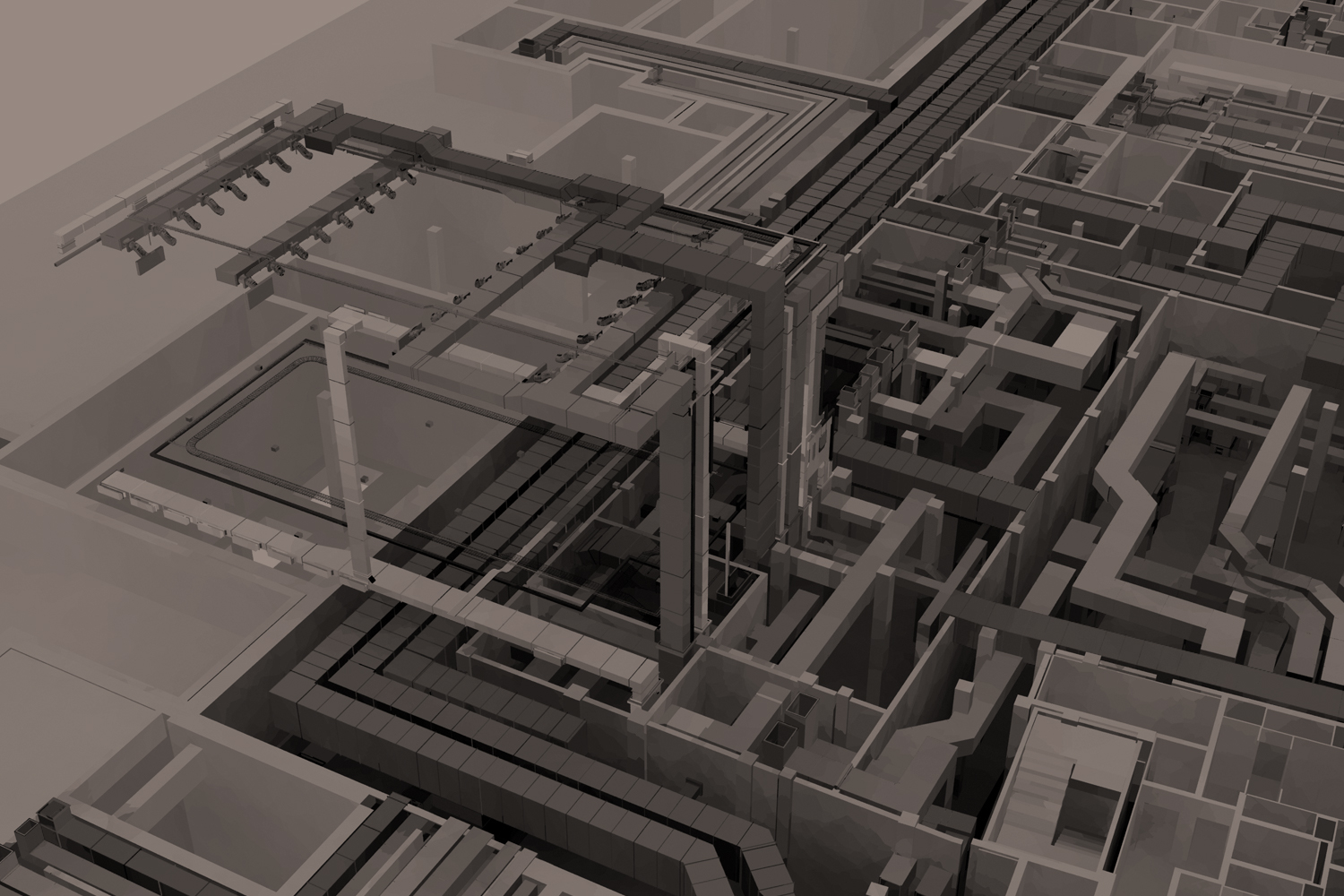

A digital twin, also known as a data twin, is a digital representation of a physical object. Outside of the built environment, digital twins have many uses in the automotive, medical, systems engineering, and aerospace industries. Digital twin technology, for instance, has been used to enhance surgical care. A digital twin is a precise digital replica of a building, group of buildings, bridge, highway, city block, or even an entire city that is being built. Data twins, virtual models, or even next-generation as-built drawings are other names for digital twins in construction.

Digital Twins In The Construction Industry

The primary advantage of digital twins in the construction industry is that they help BIM’s analytical capabilities (BIM). BIM models now feature a higher level of sophistication thanks to digital twin technology, which allows stakeholders to see the status, usage, and location of physical assets in real-time.

Resource management

The creation of an information pipeline between the office and the field is made possible by digital twins. Project stakeholders can anticipate allocation problems and assist in striking a balance between labor costs and budgets with the help of automatic data delivery. This improves the productivity and affordability of the job site.

Streamlined asset management

Digital twins can take on a lot of the workload normally associated with asset management. For instance, a digital twin can identify problem areas and provide technicians with the necessary specifications when a repair is required. It can even remember who needs to be charged for the work.

Improved efficiency

To do this, you must understand how the facility is being used. KONE recently examined how people use elevators using digital twins. Sensors were employed to monitor how people moved around the structures. Reduce elevator wait times, particularly in the morning rush.

Connectivity

A centralized platform is used to deliver information by digital twins. By automatically updating 3D models with constructible data, this technology expands on BIM. Content-enabled models can include component dimensions, model specifics, working conditions, and more. In this manner, as a model changes over time alongside a building, no details are lost.

After the initial building is finished, the advantages of digital twins continue to exist. They continue to provide resourceful answers for common asset usage.

Why is the digital twin important in construction?

To close the gap between form and function, digital twins are used in construction. Space is represented on paper as a set of measurements in a blueprint. It is a component of a bigger structure being built. Planners must have foresight when choosing a purpose for that area. Who will employ it, How will they employ it and Which resources will reside there This data is compiled by the digital twin.

A digital twin serves as a link between building design and management because it is still helpful after construction is finished. For instance, a smart building will incorporate powerful connected technology during the building process.

Future of digital twins

The construction industry is anticipated to continue changing as a result of digital twins. A 2020 study estimated that by 2026, the market for digital twins would reach $48.2 billion. New technologies are enabling the development of more precise digital models. Construction automation and robotics will continue to develop and be embraced by the industry. digital twin starter sets could be a source of revenue for contractors. More mobile scanning robots will be used by digital smart asset systems to collect real-time data, which is essential for the development of successful digital twins.

Urban modeling is also utilizing digital twin technology more and more. Digital twins are being used by cities and municipalities to develop smart cities. For planning purposes, such as population growth and climate change modeling, an entire city is digitalized.

One thing will always be true, regardless of how the technology is applied: Digital twins improve BIM capabilities by enabling truly constructible processes. Models that can track, store, and display complex data instantly aid in providing important, useful information throughout all phases of construction and for years to come. Digital twins are the future of construction, from bidding to the building.

FAQ

What are the types of digital twins?

In general, there are three different types of digital twins: performance, production, and product.

Is digital twin a 3D model?

A digital twin is a replica in the digital realm of a physical location or thing. The development of digital twins, which are dimensionally accurate 3D digital models that can be quickly updated to reflect changes with their physical counterparts, is made possible by artificial intelligence and machine learning technologies.

Why do we need a digital twin?

Companies can test and validate a product before it even exists in the real world with the support of a digital twin. A digital twin enables engineers to find any process flaws before the product is put into production by simulating the intended production process.

How are construction digital twins accessed?

Through specialized software, such as Trimble Connect, Quadri, Agile Assets, or Tekla, one can access digital twins. For the storage and sharing of digital twins, these systems provide project stakeholders with a centralized, single source of truth.

What are the challenges of the digital twins?

The digital twin can also be used to gather a wealth of information about how customers use a product and use that information to spot potential problems, conduct remote troubleshooting, and remove any unnecessary features or components.

What difficulties does the digital twin face?

The following challenges must be overcome by digital twins in order to achieve these capabilities.

- Accurate Physical Property Capturing.

- Project Collaboration.

- Real-Time Automatic Update.

- Finding and resolving conflicts

- Interaction with both physical and digital objects.